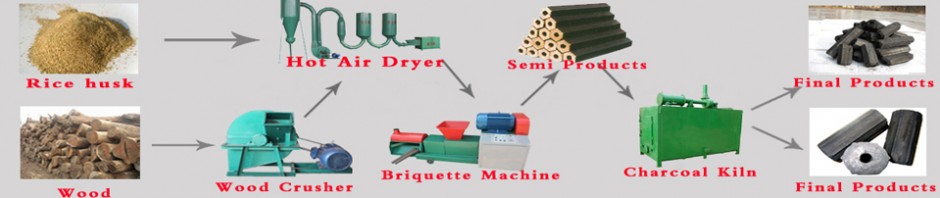

With the current economical state, a lot of people have had bad times especially when it comes to the high fuel costs. A majority of them have come up with options that they can use as a way of cutting down fuel costs. One of the best ways is through briquetting. One can easily come up with wood briquettes or charcoal briquettes easily as long as you have the right equipment to do that. In addition to this, you are supposed to have all the raw materials available to make the briquetting process worthwhile.

Briquettes machinery is very important when it comes to making briquettes. This machinery can be used for many applications such as recycling, shredding, volume reduction, removing water & oil, production of fodder and lastly in the compaction of filter dusts. While this is the case, it is therefore important to choose machinery that matches your needs effectively.

There are some benefits that come with briquettes machinery which makes it to be among the most sought for machinery when it comes to briquetting. This machinery has a rugged construction which makes it easier to be utilized in putting the raw materials. It does not wear that easily which means that it can stay for a long period of time as long as it is well maintained. The machinery comes with a low electrical load as compared to the briquette capacity. When it comes to handling and shipping, the costs are very low which means that an individual can easily afford the machinery.

Categories

-

Recent Posts

The idea of making briquettes out of sawdust, coal or biomass helps in a large way in eliminating waste while at the same time creating fuel that is considered to have a higher value compared to charcoal and wood. Briquettes making machine is basically used for making briquettes that give off very little smoke and at the same time maintaining a steady temperature. The best thing about this machine is that it produces several briquettes in a short period of time.

The idea of making briquettes out of sawdust, coal or biomass helps in a large way in eliminating waste while at the same time creating fuel that is considered to have a higher value compared to charcoal and wood. Briquettes making machine is basically used for making briquettes that give off very little smoke and at the same time maintaining a steady temperature. The best thing about this machine is that it produces several briquettes in a short period of time. When using a briquettes making machine, it is important to mix the sawdust first ensuring that it is all saturated. In most cases, these machines come with molds and as such, it is important to pour all the mixture in the mold. Once done, close the machine carefully over the mold so that enough pressure can be applied in order to create the briquettes. It is important to ensure that the machine is closed for the precise time that has been specified on it. It is usually about some hours for the briquettes to be created.

When using a briquettes making machine, it is important to mix the sawdust first ensuring that it is all saturated. In most cases, these machines come with molds and as such, it is important to pour all the mixture in the mold. Once done, close the machine carefully over the mold so that enough pressure can be applied in order to create the briquettes. It is important to ensure that the machine is closed for the precise time that has been specified on it. It is usually about some hours for the briquettes to be created.